Blog

December Update - Micro-ROV, Automatic Stabilization

2019 Status Update

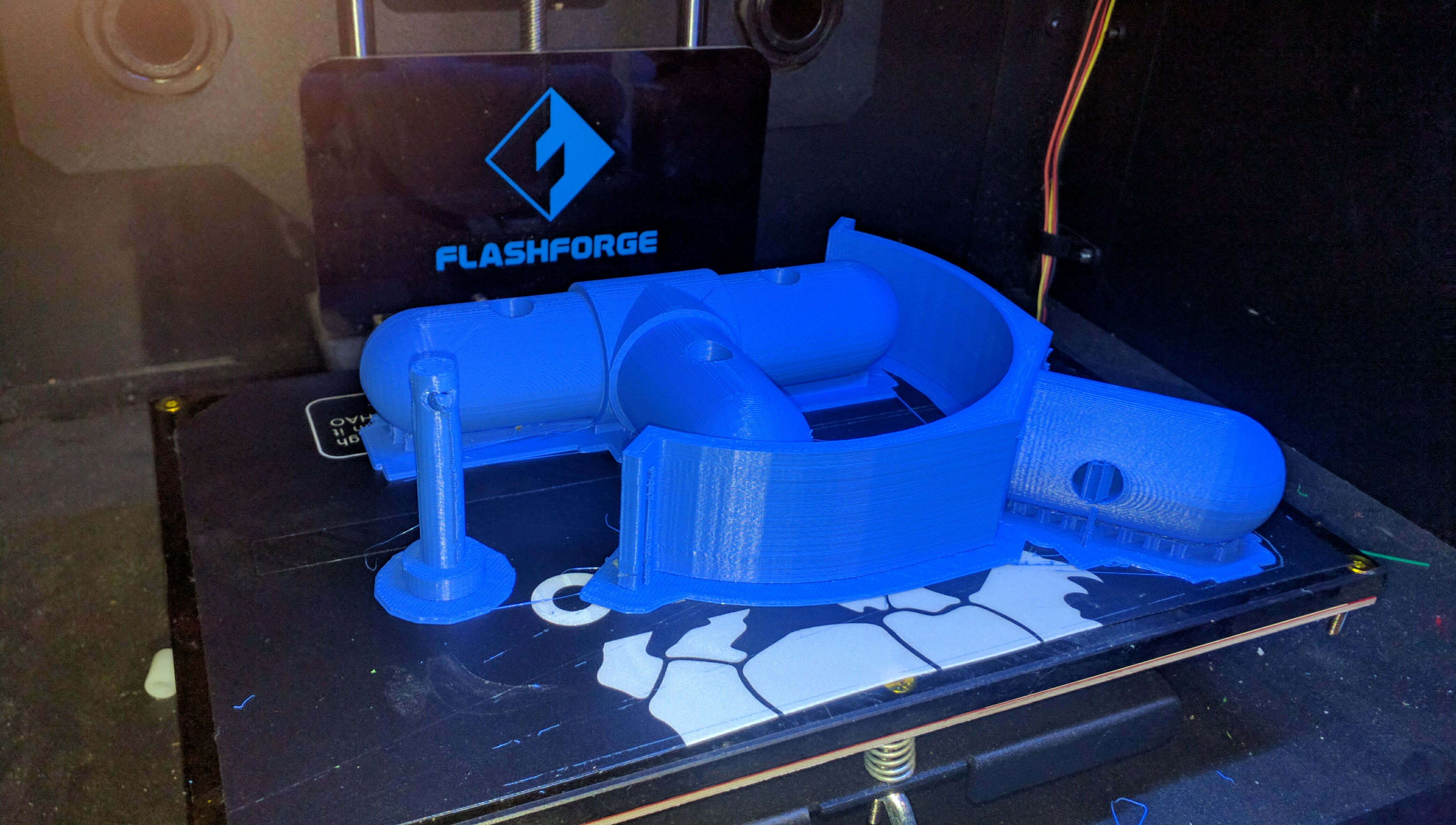

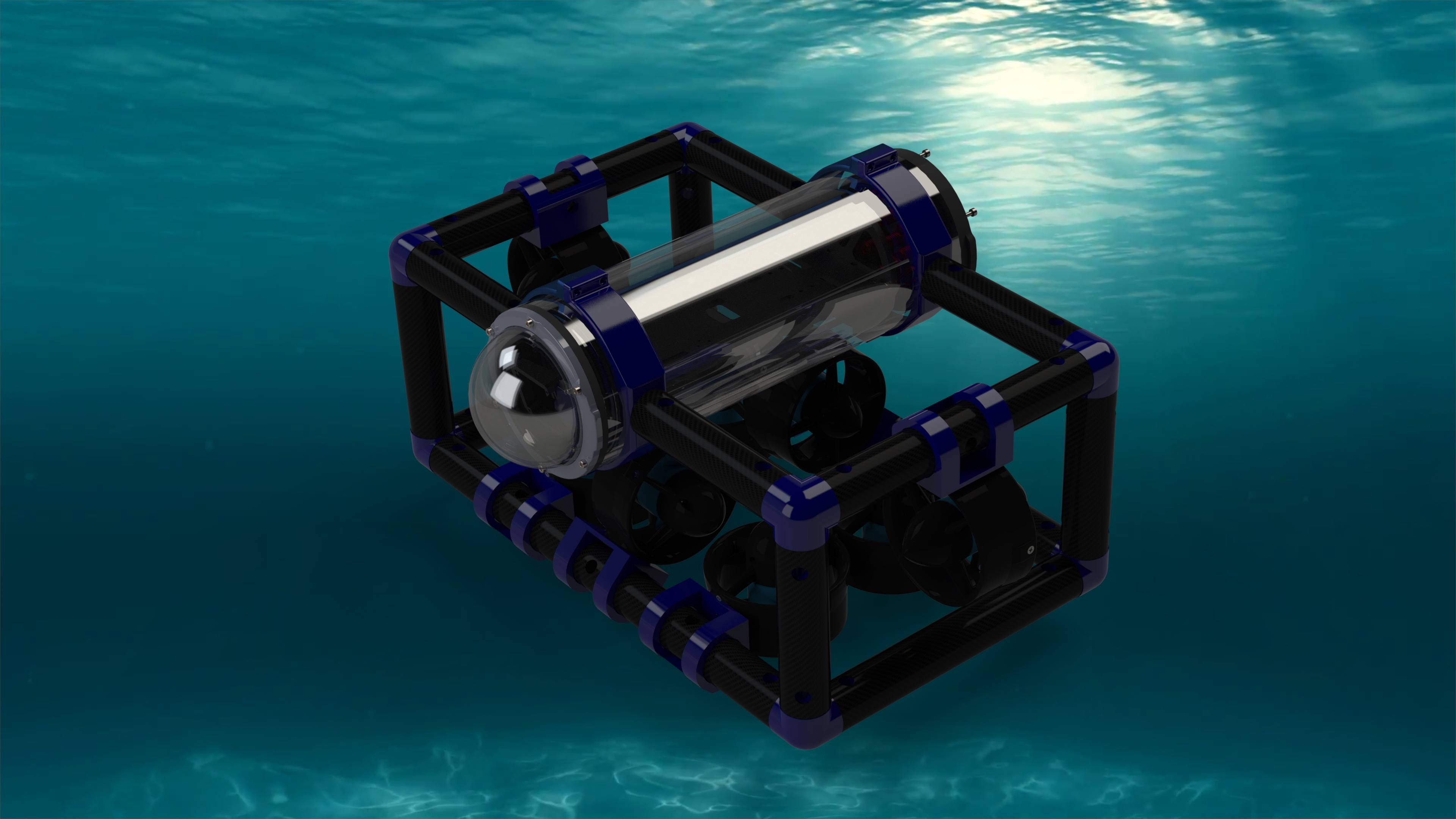

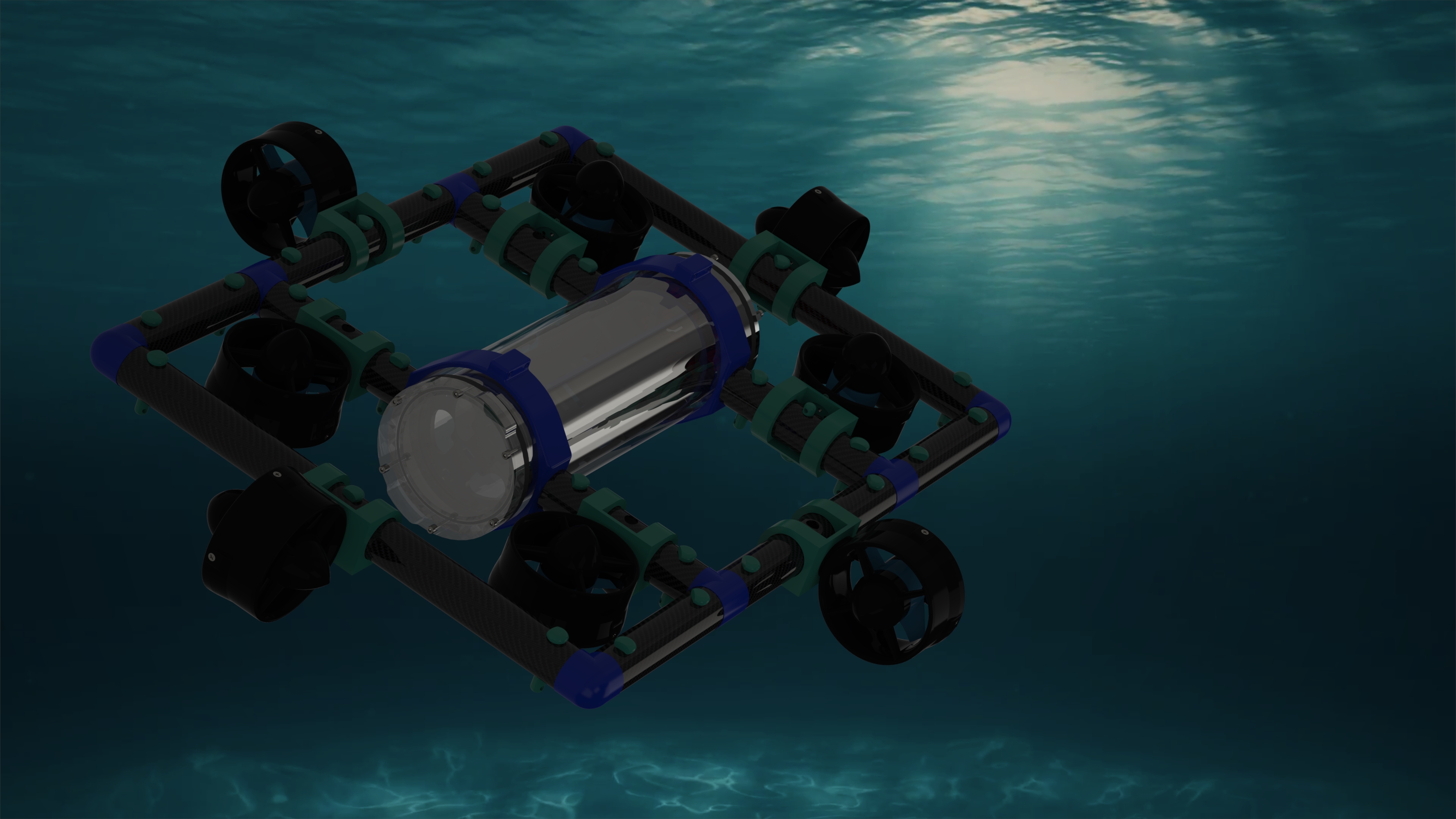

Modified ROV Frame

We modified the layout of our ROV to eliminate certain flaws from our previous layout, including buoyancy issues and overall size (see photos below). The new design is much smaller, giving us easier maneuverability in the water, and fewer issues with transportation.

Recruitment

It is the beginning of the school year, and Subsea Rovers is looking for new recruits! We have updated our recruitment page, and we are looking for ways to reach out to people who may wish to join our team. If you are interested in joining, contact us or learn more on our recruitment page.

Rocklin Mini Maker Faire

On October 6th, our team made an appearance at the Rocklin Mini Maker Faire at Sierra College. We were even interviewed by Good Day Sacramento! We explained and demonstrated our ROV to attendees of the Faire, and may have found some new team members. We have many other ideas concerning possible manipulators, fundraising, recruitment, improving the website, team productivity, and more. Follow along with us this year as we build our newest ROV!